Improvements in Diamond Grinding Tool Coatings for Better Results2024-11-26

The effectiveness of diamond grinding tools is important in sectors such as construction, manufacturing, and restoration. As the need for greater efficiency and precision increases, the significance coatings on these tools has gained attention. Recent innovations in coating technologies are revolutionizing diamond grinding tools, leading to improved performance and longer durability.

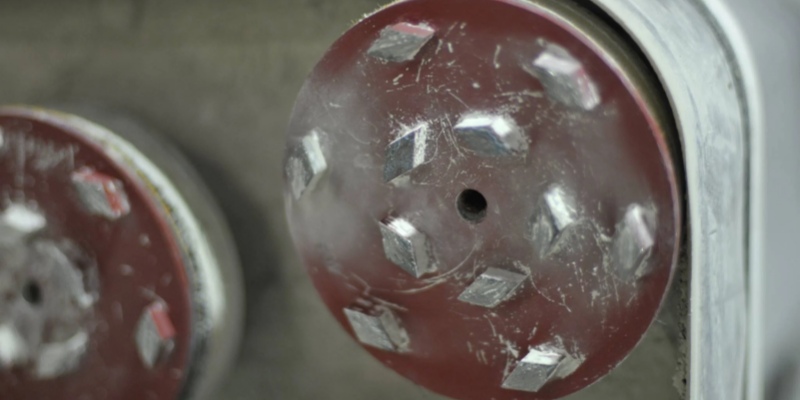

A major advancement in diamond grinding tooling coatings is the introduction of sophisticated bonding agents. These coatings enhance the retention of diamond particles, minimizing the risk of early wear of detachment. This not only boosts the tool’s cutting and grinding efficiency but also ensures a uniform finish on various materials, including concrete and stone.

Moreover, the thermal stability of modern coatings has proven to be transformative. The high temperatures generated during grinding can cause tools to overheat, which diminishes their effectiveness. New heat-resistant coatings help preserve the integrity of the tools even in extreme conditions, reducing downtime and enhancing productivity. This is especially advantageous for demanding tasks such as floor restoration and industrial material processing.

Another significant development in coatings is their friction-reducing properties. Low-friction coatings facilitate smoother operation by decreasing resistance between the tool and the material being processed. This not only accelerates work speed but also lowers the energy consumption of grinding machines, making the process more economical and eco-friendly.

The outlook for diamond grinding tool coatings is bright, with ongoing research into nanotechnology and self-healing materials. These innovations aim to produce tools that can adapt to wear, ensuring reliable performance throughout their lifespan.

By opting for TransGrind diamond grinding tool with advanced coatings, people can achieve exceptional results, enhance operational efficiency, and lower long-term expenses. These advancements highlight the ongoing progress in diamond grinding technology.

- Company Info

- Feedback

- Customer Reviews

- About Us

- Contact Us

- Blog

- Help Center

- User Center

- Forget Password

- My Orders

- Tracking Order

- My Account

- Register